Xingxing Casting Industry Iron Pipe Co.,Ltd.

Xingxing Casting Iron Pipe (义乌市宜骋贸易有限公司) Co., Ltd. Since its establishment in 2007, Xingxing Casting Iron Pipehas been adhering to the principles of “good reputation, competitiveness, strong development, and sincere cooperation.” With a focus on the quality policy of putting people first and adopting a lean approach to casting, Xingxing Casting Iron Pipe aims to establish itself as a global brand in the casting field. As a domestic enterprise, it has won numerous awards as “Emerging Private Enterprise,” “AAA Enterprise Trust,” and “Advanced Tax Unit.” Our cast iron products include ductile iron drain pipes with ductile iron joints, flexible cast iron drain pipes, ductile iron pipes, drainage pipes, ductile manhole covers, city covers, and other applications. We strive to provide a variety of castings for civil applications, public buildings, and municipal engineering to meet the diverse needs of customers. We are also building a professional platform for investors, managers, and employees. Together, we will contribute to the construction of social wealth, promote scientific and technological progress, and share the fruits of development. We are committed to continuing our work. Xingxing Casting Iron Pipe will be the ideal choice and pride of every participant and partner. Xingxing Casting Iron Pipe will continue to innovate, and the appreciation of our customers is our greatest support! We are willing to cooperate with colleagues from all walks of life to create wonderful works.

PRODUCTION PROCESS

Preparation of hot meta

Blast furnace ironmaking: The quality of hot metal is closely related to the composition of raw materials. Our company tests each batch of raw materials, refines low-phosphorus and low-sulfur hot metal, and ensures that the content of carbon, phosphorus and sulfur in the hot metal meets the requirements.

Centrifugal casting

Centrifugal casting: Our company uses the water metal process for centrifugal casting. The molten iron at about 1360C after melting in the electric furnace is continuously poured into the high-speed rotating pipe mold, and the molten iron is solidified by water cooling to form a ductile iron pipe. Quality control: The cast ductile iron pipe is immediately inspected for casting defects on the surface to ensure the quality of the centrifugally cast ductile iron pipe.

Finishing

Weighing: Use electronic scale to weigh each ductile iron pipe to ensure that the weight of the pipe meets the quality standard requirements. Zinc spraying: In order to further enhance the corrosion resistance of ductile iron centrifugal cast iron pipes, zinc spraying is required on the outer surface of the pipe. Metal zinc spraying is used, and the material is metal zinc with a zinc content of more than 99%. The weight of the zinc layer is not less than 130g/m’, and the weight of the zinc layer in any area is not less than 110g/m’. To ensure the quality of zinc spraying, zinc spraying should be carried out after the heat treatment process is completed and the pipe body itself is still at a certain temperature.

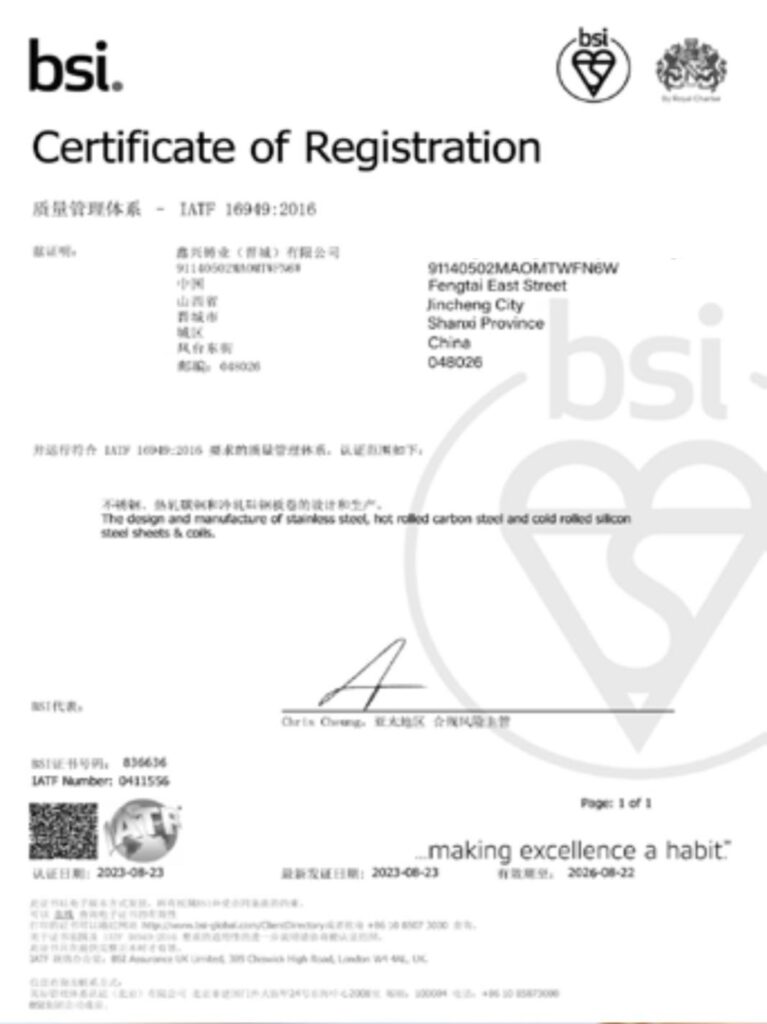

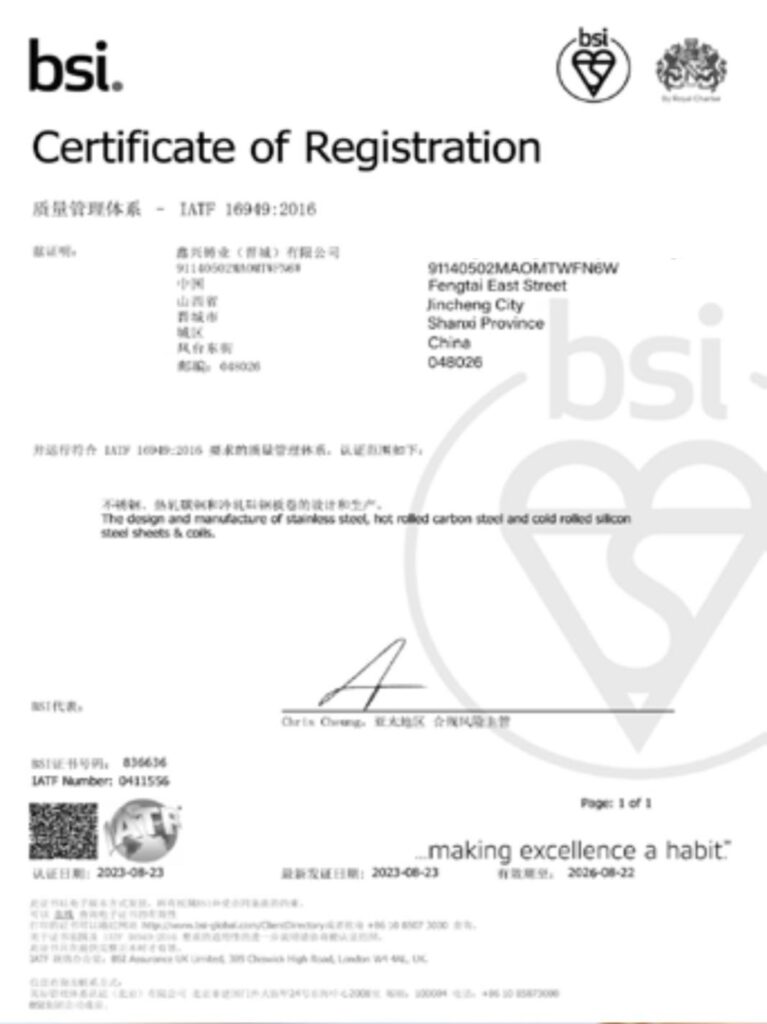

HONOR